Building a Solid Base: Your Guide to Manufactured Home Foundation Types

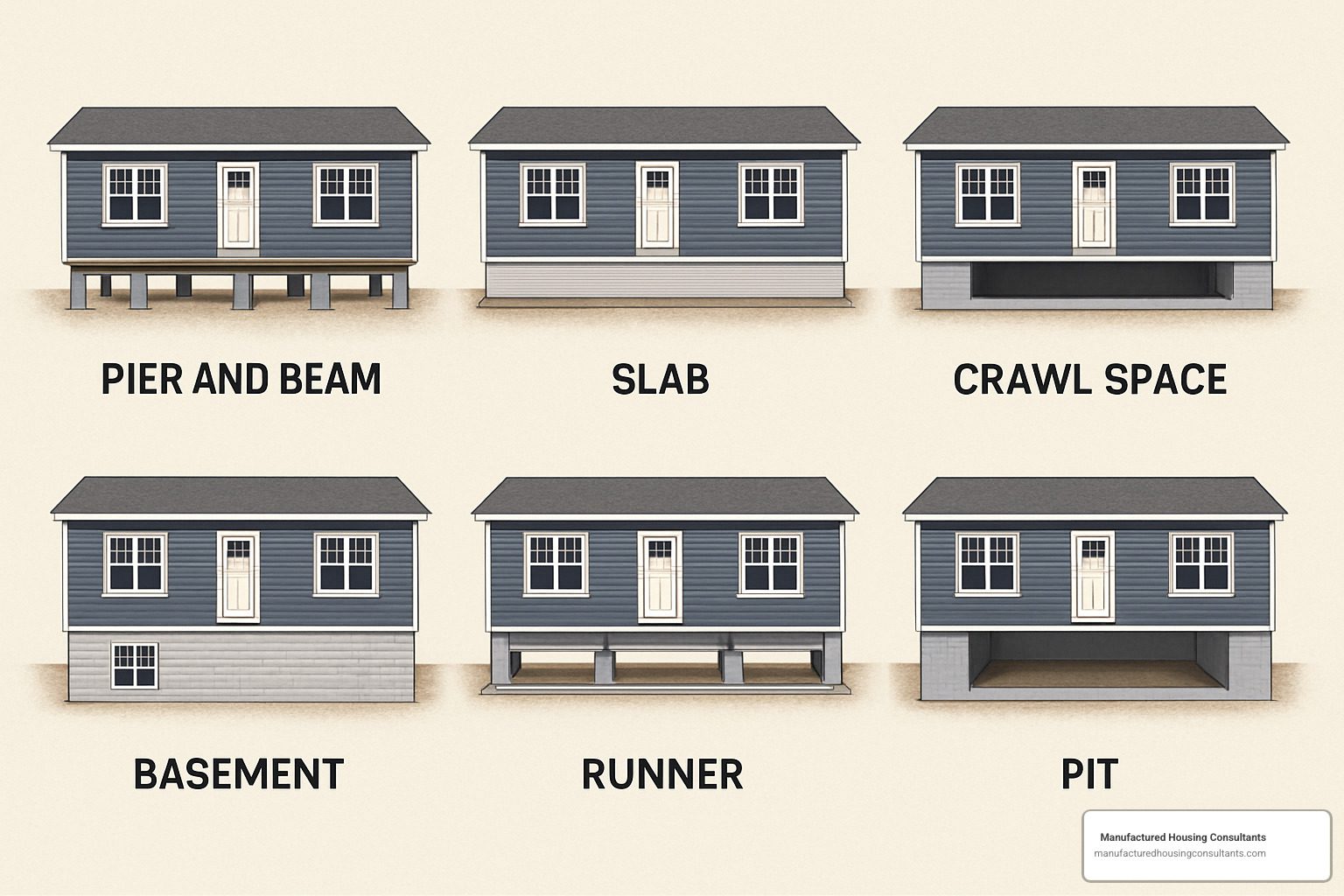

Manufactured home foundation types include pier and beam, slab, crawl space, basement, runner, and pit foundations. Each type varies in cost, installation time, and suitability for different climates and site conditions.

| Foundation Type | Cost Range | Installation Time | Best For | Permanent? |

|---|---|---|---|---|

| Pier and Beam | $1,000-$2,000 | 1 day | Affordability, flood/seismic zones | No |

| Slab | $4,000-$9,000 | 3-5 days | Flat lots, warm climates | Yes |

| Crawl Space | $6,000-$15,000 | 5-8 days | Sloped lots, utility access | Yes |

| Basement | $12,000-$25,000 | 10+ days | Extra living space, cold climates | Yes |

| Runner | $2,000-$8,000 | 2-3 days | Flat lots, budget options | Varies |

| Pit | $2,000-$6,000 | 3-5 days | Storage needs, sloped sites | Yes |

A home’s foundation is key to keeping it strong and secure for years to come. While site-built homes typically use traditional foundation systems, manufactured homes require specialized foundation types that consider their unique construction.

The foundation you choose matters more than you might think. It’s not just about holding your home up—it affects everything from financing options to long-term value. As HUD guidelines state, “There is no single ‘best’ foundation system.” Your choice should balance cost, site conditions, climate, and your long-term goals.

For Texas homeowners, foundation selection requires special attention to our unique soil conditions, potential for flooding, and variable climate zones. A properly selected and installed foundation can transform your manufactured home from a depreciating asset into appreciating real property.

Whether you’re buying your first manufactured home or upgrading your current foundation, understanding your options is the first step toward making a sound investment.

Manufactured home foundation types further reading:

Understanding Manufactured Home Foundation Types

When it comes to manufactured home foundation types, there’s a critical distinction that affects everything from your financing options to how much your home will be worth years from now: permanent versus non-permanent foundations.

Permanent vs. Non-Permanent Foundations

Permanent foundations are built to last as long as your home does. They’re constructed from durable materials like concrete, mortared masonry, or treated wood that meet HUD’s requirements for real property classification. What makes them “permanent” is how they transfer all the weight of your home directly to the soil or rock underneath while resisting any movement from wind, water, or earth.

Non-permanent foundations, while easier on your wallet initially, are designed with the possibility of moving your home someday. They typically use removable components like concrete blocks or metal piers that aren’t permanently attached. I’ve seen many homeowners choose these to save money upfront, only to face limitations later.

Take Michael from San Antonio, for example. He told me: “I originally chose a pier-and-beam system to save money, but when I tried to refinance, my options were limited. Upgrading to a crawl space foundation qualified me for a conventional mortgage with a much lower interest rate—it paid for itself within two years.”

What Makes Manufactured Homes Different?

Manufactured home foundation types need special consideration because these homes aren’t built like traditional site-built houses. What sets manufactured homes apart is that they’re:

Built completely in a factory environment, transported to your property on their own chassis, delivered in one or more sections, required to meet federal HUD standards (established June 15, 1976), and always carry a red HUD certification label on each transportable section.

This is quite different from modular homes, which are also factory-built but designed specifically for permanent foundations and must meet local building codes rather than HUD standards. If you’re curious about these differences, check out our guide on modular vs manufactured homes.

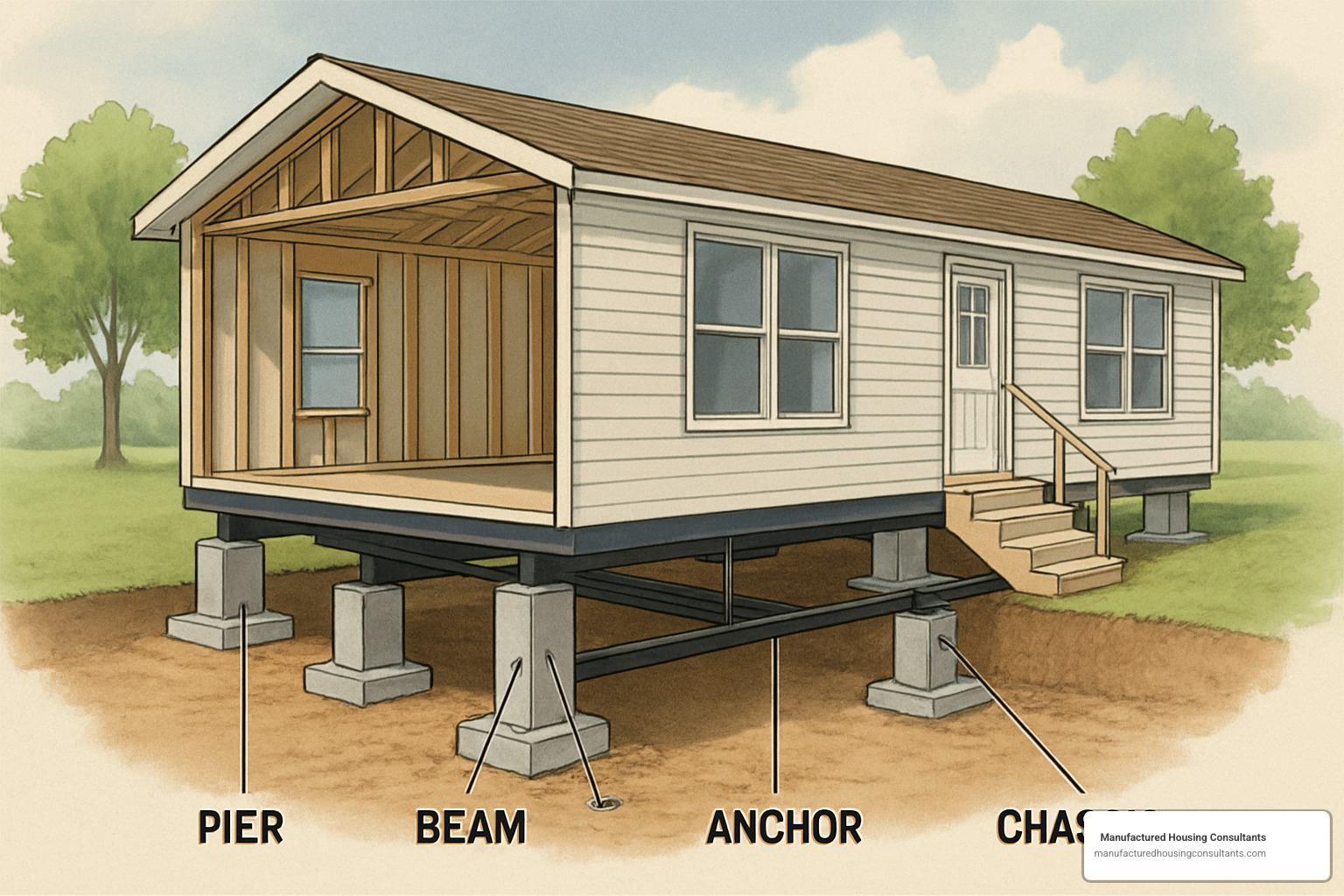

The built-in chassis of manufactured homes creates unique foundation requirements, especially in how your home attaches to its foundation and how the weight gets distributed.

Main Manufactured Home Foundation Types Explained

Let’s walk through the six main manufactured home foundation types you’ll encounter:

1. Pier and Beam Foundation

The most common and budget-friendly option you’ll see. This foundation consists of concrete blocks or steel piers placed on footings that support your home’s chassis. The typical setup includes concrete footings on stable soil, concrete blocks or steel piers, steel straps or ground anchors to keep your home secure in high winds, and skirting around the outside for both looks and protection.

This foundation works best if you’re watching your budget, live in an area with minimal frost, need elevation in a flood zone, or might want to relocate your home in the future.

2. Runner Foundation

Think of runners as long concrete paths that run the length of your home’s chassis beams. This system includes a gravel or sand base for good drainage, reinforced concrete runners (usually 12-24 inches wide), anchor points embedded right in the concrete, and optional skirting for appearance.

Runners are ideal for flat lots with good drainage, areas where the ground doesn’t freeze deeply, and when you want something more substantial than pier and beam without paying for a full concrete slab.

3. Slab-on-Grade Foundation

A slab is essentially one solid concrete pad supporting your entire home. It includes a layer of gravel or sand for drainage, 4-6 inches of reinforced concrete, thicker edges where your home bears the most weight, embedded anchor points, and in colder areas, insulation around the edges.

Slabs work beautifully on flat sites, in warm climates with minimal frost, and when you want permanent installation that qualifies for conventional financing.

4. Crawl Space Foundation

A crawl space creates an enclosed area beneath your home, typically 18-48 inches high, with walls around the perimeter. This foundation features continuous footings below the frost line, concrete or masonry walls around the edge, support piers inside, ventilation openings, moisture barriers, proper drainage, and an access door for maintenance.

This option is great for sloped lots, areas with deep frost lines, when you need easy access to plumbing and electrical, and if you want permanent installation with conventional financing options.

5. Basement Foundation

A basement gives you a full-height, below-ground space that can add valuable living or storage area. It requires deep excavation (usually 7-9 feet), reinforced concrete footings and walls, waterproofing systems, interior support columns, proper ventilation, and stairway access from your home.

Basements make sense in cold climates, when you want additional space, if you’re looking to maximize property value, and in areas where site-built homes commonly have basements.

6. Pit Foundation

A pit foundation is like a shallow crawl space, typically 18-36 inches deep. It includes an excavated area, perimeter footings with short walls, interior support piers, moisture barriers, drainage, and limited ventilation.

This foundation works well when you want your home to sit lower to the ground, on slightly sloped sites, and when you’re looking for something between the cost of pier and beam and a full crawl space.

For homes in windy areas, all manufactured home foundation types must account for your HUD wind zone:

- Wind Zone I: Most of the continental U.S. (winds up to 70 mph)

- Wind Zone II: Parts of the Gulf and Atlantic coastlines, including eastern Texas (winds up to 100 mph)

- Wind Zone III: Coastal areas most susceptible to hurricanes (winds up to 110 mph)

Here in Texas, we deal with all three wind zones, which is why proper anchoring is essential no matter which foundation you choose.

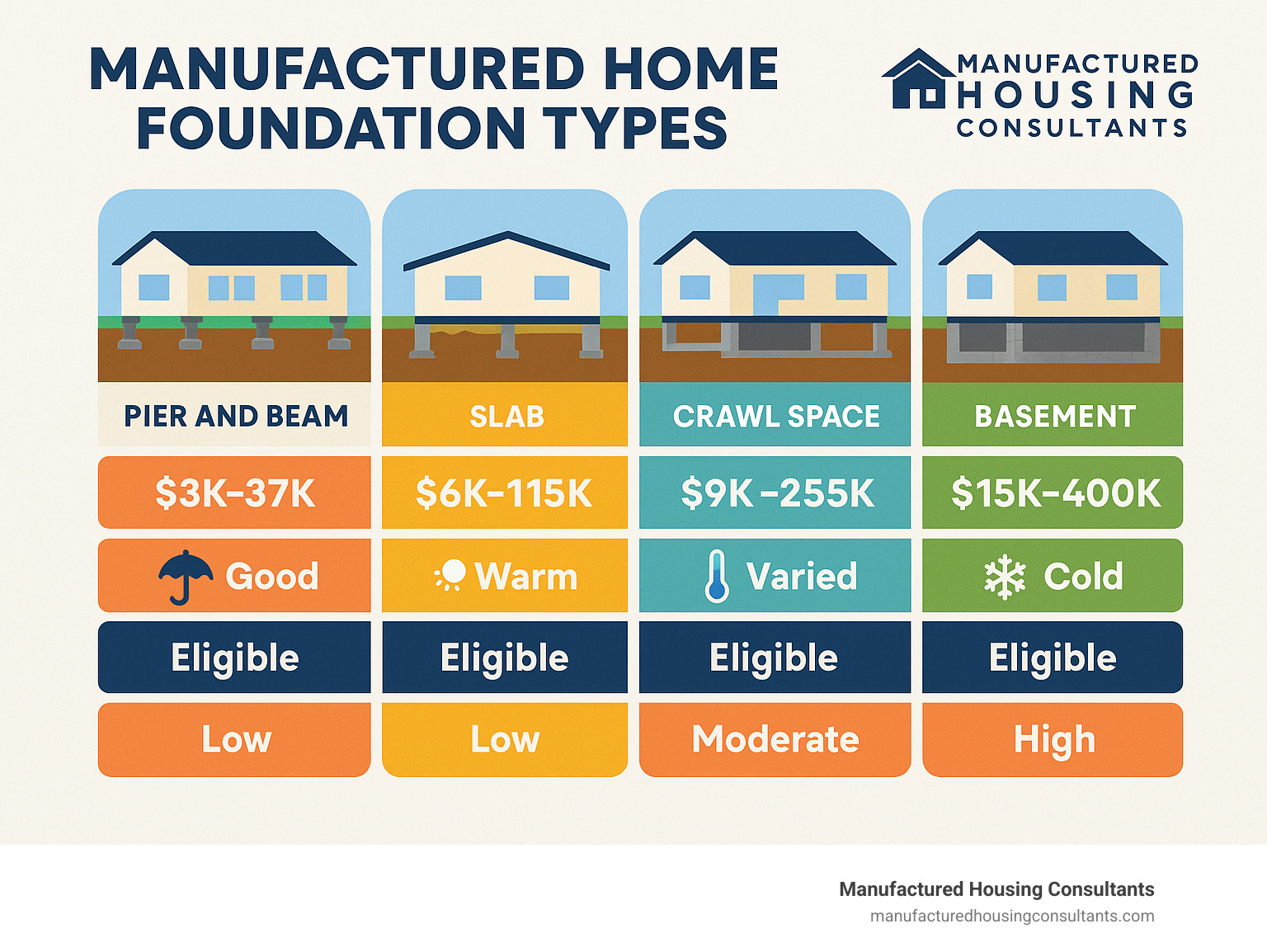

Manufactured Home Foundation Types: Pros, Cons & Costs

When comparing manufactured home foundation types, consider these important factors:

| Foundation Type | Pros | Cons | Cost Range | Installation Time | Climate Suitability | Financing Eligibility | Maintenance Needs |

|---|---|---|---|---|---|---|---|

| Pier and Beam | • Most affordable • Quick installation • Good in flood zones • Easily accessible utilities • Performs well in seismic areas |

• Not the most attractive • May require re-leveling • Limited financing options • Potential for floor sagging • Less energy efficient |

$1,000-$2,000 | 1 day | Good for flood zones and mild climates; poor for high frost areas | Limited; typically chattel loans only | Re-leveling every 3-5 years; regular anchor checks |

| Runner | • Cost-effective • Better stability than pier/beam • Good utility access • Relatively quick installation |

• Not suitable for sloping lots • Poor in seismic areas • Limited in high frost areas • May not qualify as permanent |

$2,000-$8,000 | 2-3 days | Best in dry, stable soil areas with minimal frost | Varies by lender; may qualify for some conventional loans | Periodic checking for settling or cracking |

| Slab | • Solid, stable platform • Moisture resistant • Qualifies as permanent • Good in warm climates • Low maintenance |

• Difficult utility access • Not suited for sloped lots • Higher repair costs if issues arise • Poor in freeze/thaw cycles without proper insulation |

$4,000-$9,000 | 3-5 days | Excellent for warm, dry climates; needs special design for frost areas | Eligible for conventional, FHA, VA loans | Minimal; annual inspection for cracks |

| Crawl Space | • Good utility access • Works well on slopes • Qualifies as permanent • Good in frost areas • Better insulation potential |

• Higher cost • Longer installation time • Requires moisture control • Potential pest issues |

$6,000-$15,000 | 5-8 days | Versatile; good for most climates with proper design | Eligible for conventional, FHA, VA loans | Periodic moisture checks; ventilation maintenance |

| Basement | • Adds living/storage space • Highest resale value • Excellent in cold climates • Storm shelter potential • Best energy efficiency |

• Most expensive option • Longest installation time • Potential moisture issues • Not suitable in high water table areas |

$12,000-$25,000 | 10+ days | Excellent for cold climates; challenging in high water table areas | Eligible for all financing types | Moisture monitoring; periodic checks of waterproofing |

| Pit | • Lower profile appearance • More affordable than full crawl space • Some utility access • Can qualify as permanent |

• Limited headroom for access • Potential drainage issues • Not ideal in high water table areas |

$2,000-$6,000 | 3-5 days | Good for moderate climates; not ideal for high water table areas | Often eligible for conventional financing | Moisture monitoring; limited access for repairs |

Industry data shows that modern manufactured homes placed on permanent foundations (slab, crawl space, or basement) on land you own can actually appreciate at nearly the same rate as traditional site-built homes. That makes your foundation choice one of the most important investment decisions you’ll make.

Getting Your Foundation Certified & Compliant

For your manufactured home foundation types to qualify as permanent under HUD guidelines, they need to meet the requirements in HUD’s Permanent Foundations Guide for Manufactured Housing (PFGMH). This is particularly important if you’re hoping to get FHA, VA, or conventional financing.

The key requirements include using durable materials that will last at least 30 years, ensuring your foundation transfers all weight to the earth and can resist sliding or overturning, protecting against frost, removing all wheels and transportation equipment, getting certification from a licensed engineer, creating an enclosed space beneath your home with proper access and ventilation, and installing permanent utility connections.

For FHA Title II loans, you’ll also need to make sure your home is classified as real property, properly installed on a permanent foundation, meets Model Manufactured Home Installation Standards, and has an attached HUD Certification Label.

As one of our New Braunfels customers shared: “The engineer certification seemed like an unnecessary expense at first, but it was worth every penny when we qualified for an FHA loan with a 3.5% down payment instead of the 10-20% required for a chattel loan.”

For more detailed information on HUD requirements, you can check out the HUD Permanent Foundations Guide for Manufactured Housing.

Choosing, Maintaining & Financing the Best Manufactured Home Foundation

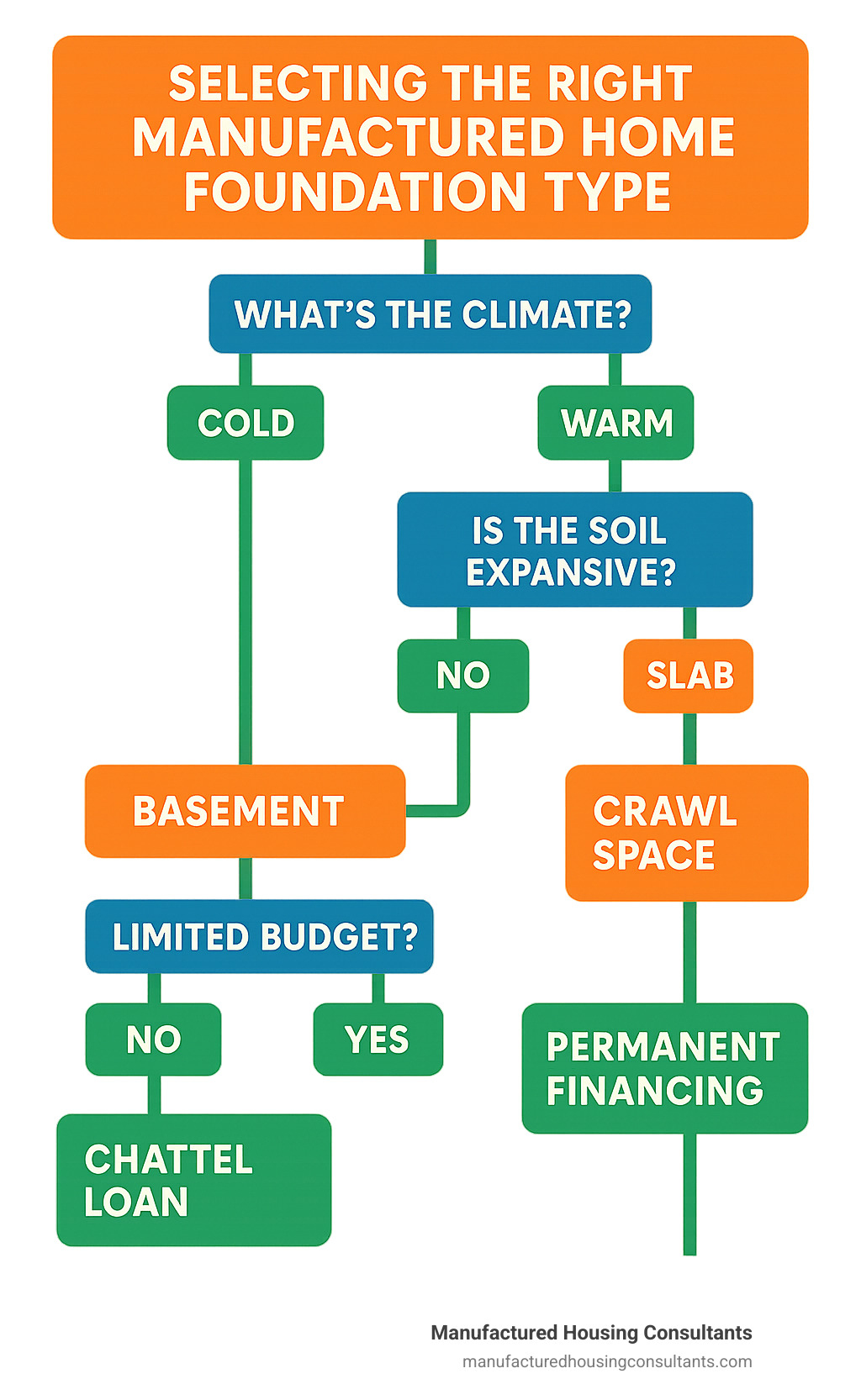

Selecting the right foundation from available manufactured home foundation types requires careful consideration of several factors:

Site Assessment and Preparation

Before you commit to a foundation, it’s worth taking time to understand what’s beneath your feet. Your soil tells a story that directly impacts your home’s future.

Soil type and bearing capacity vary dramatically across Texas. Sandy soils drain well but might need larger footings to distribute weight properly. Clay soils, common in many parts of San Antonio and Central Texas, tend to expand when wet and contract when dry – a dance that can stress foundations over time.

The slope and drainage of your property matters too. While flat sites play nicely with slab or runner foundations, those hillside views might require a crawl space or basement approach. As Maria from New Braunfels finded, “We loved our sloped lot for the views, but our builder recommended a crawl space foundation. Now we appreciate both the view and the stable foundation beneath us.”

In areas with freezing temperatures, frost depth becomes crucial. Footings need to extend below the frost line – which can range from 12 to 48 inches depending on your location – or use specialized frost-protected techniques. Even in our warm Texas climate, those in the Panhandle or higher elevations need to account for this.

Flood risk assessment is non-negotiable in many parts of Texas. If you’re in a floodplain, liftd foundations like pier and beam or properly designed crawl spaces aren’t just smart – they’re often required. FEMA regulations may dictate specific elevation requirements above base flood level.

Texas spans multiple HUD wind zones, which affects how your home needs to be anchored. Our coastal areas require particularly robust anchoring systems to withstand hurricane-force winds.

The water table beneath your property can make certain foundation types impractical. A high water table might make a basement a constant battle against moisture, while requiring special controls for crawl spaces.

Finally, local building codes vary across Texas counties and municipalities. What works in Laredo might not meet code in Corpus Christi.

We typically recommend investing in a professional soil test ($300-$1,000) before finalizing your foundation choice. As we often remind our San Antonio customers, “You can change almost anything about your home later, but changing the foundation is extremely difficult and expensive.” That small upfront investment can prevent major headaches down the road.

Climate Considerations for Texas Regions

Texas is like several states rolled into one when it comes to climate, and your foundation needs to match your local conditions.

Along the Gulf Coast (including Corpus Christi), you’re dealing with high humidity, hurricane risk, and occasional flooding. Here, liftd foundations like pier and beam or crawl space with serious anchoring systems tend to perform best. As one customer in Portland told us, “After seeing what happened to slab homes during the last big storm, I’m glad we went with a crawl space that kept us high and dry.”

In Central Texas (including San Antonio and New Braunfels), we see everything from flooding to drought, sometimes in the same year! Crawl space foundations often provide the best balance here, offering stability while managing moisture challenges. The liftd design also provides some protection during those surprise flash floods that can sweep through our creek beds and low-lying areas.

South Texas (including Laredo and Victoria) brings heat and often expansive clay soils. Slab foundations can work beautifully here, but they need proper site preparation to account for soil movement. The key is working with contractors who understand local soil conditions and prepare accordingly.

Across all regions, energy efficiency should factor into your decision. Crawl spaces and basements typically offer better insulation opportunities than pier and beam systems. In our Texas summers, that can translate to significant savings on cooling costs and more comfortable living.

Long-Term Maintenance Requirements

Every foundation type needs some TLC, but maintenance needs vary significantly across manufactured home foundation types.

With pier and beam foundations, regular check-ups are part of homeownership. You’ll want to check for level every 6-12 months and typically re-level every 3-5 years. After big storms, inspect those anchors – they’re your home’s seatbelts during high winds. Don’t forget to maintain proper skirting and ventilation to keep critters out and moisture moving.

Runner and slab foundations need less frequent attention but still benefit from annual inspections for cracks or settling. Maintaining proper drainage away from the foundation is crucial – even a small slope change can direct water toward your home instead of away from it. When you spot small cracks, seal them promptly before they become big problems.

Crawl space and pit foundations require vigilance about moisture. Regular checks of ventilation systems, monitoring for pest intrusion, and ensuring proper drainage will keep these foundation types performing well for decades.

If you opt for a basement foundation, watch for water intrusion, especially after heavy rains. Maintain sump pumps and drainage systems, and check for cracks in walls that might allow moisture to seep in.

Tom from Corpus Christi shared a valuable lesson: “After our first heavy rain, we noticed water pooling near the foundation. Installing a simple swale to redirect water away from the home saved us from potential moisture problems down the road.” Sometimes the simplest fixes prevent the biggest headaches.

Financing Implications

Your choice among manufactured home foundation types dramatically impacts your financing options – and potentially saves (or costs) you tens of thousands of dollars over your loan term.

With non-permanent foundations (typically pier and beam), you’re usually limited to chattel loans (personal property loans). These come with higher interest rates (often 2-5% higher than conventional mortgages), shorter terms (typically 15-20 years instead of 30), and larger down payments (usually 10-20%). That can mean significantly higher monthly payments.

Choose permanent foundations (slab, crawl space, basement), and suddenly you’re eligible for conventional mortgages, FHA loans (with down payments as low as 3.5%), VA loans (with 0% down for qualified veterans), and USDA loans in rural areas. These typically offer lower interest rates and 30-year terms.

The difference? On a $100,000 home, you might pay $200-300 less per month with a conventional mortgage versus a chattel loan. Over the life of the loan, that’s potentially $60,000-90,000 in savings – often far more than the additional cost of installing a permanent foundation.

Making Your Decision

When choosing among manufactured home foundation types, think of it as balancing several key factors:

Your budget matters both now and later. Consider not just what you can afford for installation, but how your choice affects long-term financing options. Sometimes spending a bit more upfront saves substantially over time.

Your property’s site conditions – soil, slope, drainage, frost depth, and flood risk – may make certain foundation types more practical than others. Work with the land you have, not against it.

Local climate patterns should guide your decision. What works in dry West Texas might invite disaster in humid East Texas.

Consider your long-term plans too. How long do you expect to stay in this home? Might you want to relocate it someday? Some foundations make future moves impossible, while others preserve that flexibility.

Your financing goals matter tremendously. If you’re planning to use VA, FHA, or conventional financing, your foundation must meet specific requirements.

Finally, think about resale value. The right foundation choice can help your manufactured home appreciate similarly to site-built homes, while the wrong choice might limit your buyer pool when it’s time to sell.

At Manufactured Housing Consultants, we help customers throughout San Antonio, New Braunfels, Laredo, Corpus Christi, Victoria, and all of Texas make informed decisions about manufactured home foundation types. Our team can connect you with qualified foundation contractors and guide you through the certification process.

We’ve seen how the right foundation choice transforms a manufactured home from simply a place to live into a valuable, appreciating asset. Whether you’re looking for a cozy single-wide or a spacious double-wide for your growing family, we’ll help you build on a solid foundation.

For more information on related topics, check out our guides on modular home foundation types and what type of mobile home is best for you.

Your foundation is literally what your home stands on—it’s worth taking the time to get it right. Contact us today to discuss your specific needs and let us help you find the perfect foundation solution for your manufactured home.