Understanding Today’s Modular House Prices: What You Need to Know

Modular house prices typically range from $80 to $160 per square foot fully installed, with base units starting at $50 to $100 per square foot. For quick reference:

| Modular Home Type | Average Cost Range (2025) | Average Size |

|---|---|---|

| Base Price (unit only) | $50-$100 per sq. ft. | Varies |

| Full Installation | $80-$160 per sq. ft. | Varies |

| Average Total Project | $180,000-$360,000 | 1,800 sq. ft. |

| Small/Tiny Modular | $65,000-$150,000 | 600-1,200 sq. ft. |

| Standard Ranch | $150,000-$250,000 | 1,500-2,000 sq. ft. |

| Two-Story Modular | $250,000-$350,000 | 2,000-3,000 sq. ft. |

| Custom Luxury | $300,000-$600,000+ | 2,500+ sq. ft. |

If you’re exploring affordable housing options in today’s challenging market, modular homes offer a compelling solution. Built in climate-controlled factories and assembled on-site, these homes combine quality construction with significant cost savings compared to traditional stick-built houses.

The appeal is clear: modular construction typically costs 10-20% less than conventional building methods, with construction times reduced by 30-60%. For budget-conscious buyers in states like Texas and Pennsylvania, this means getting more home for your money without sacrificing quality or customization options.

Unlike manufactured homes (often called mobile homes), modular houses are permanent structures built to the same local building codes as site-built homes. This means they appreciate in value similarly to traditional homes, making them a sound long-term investment.

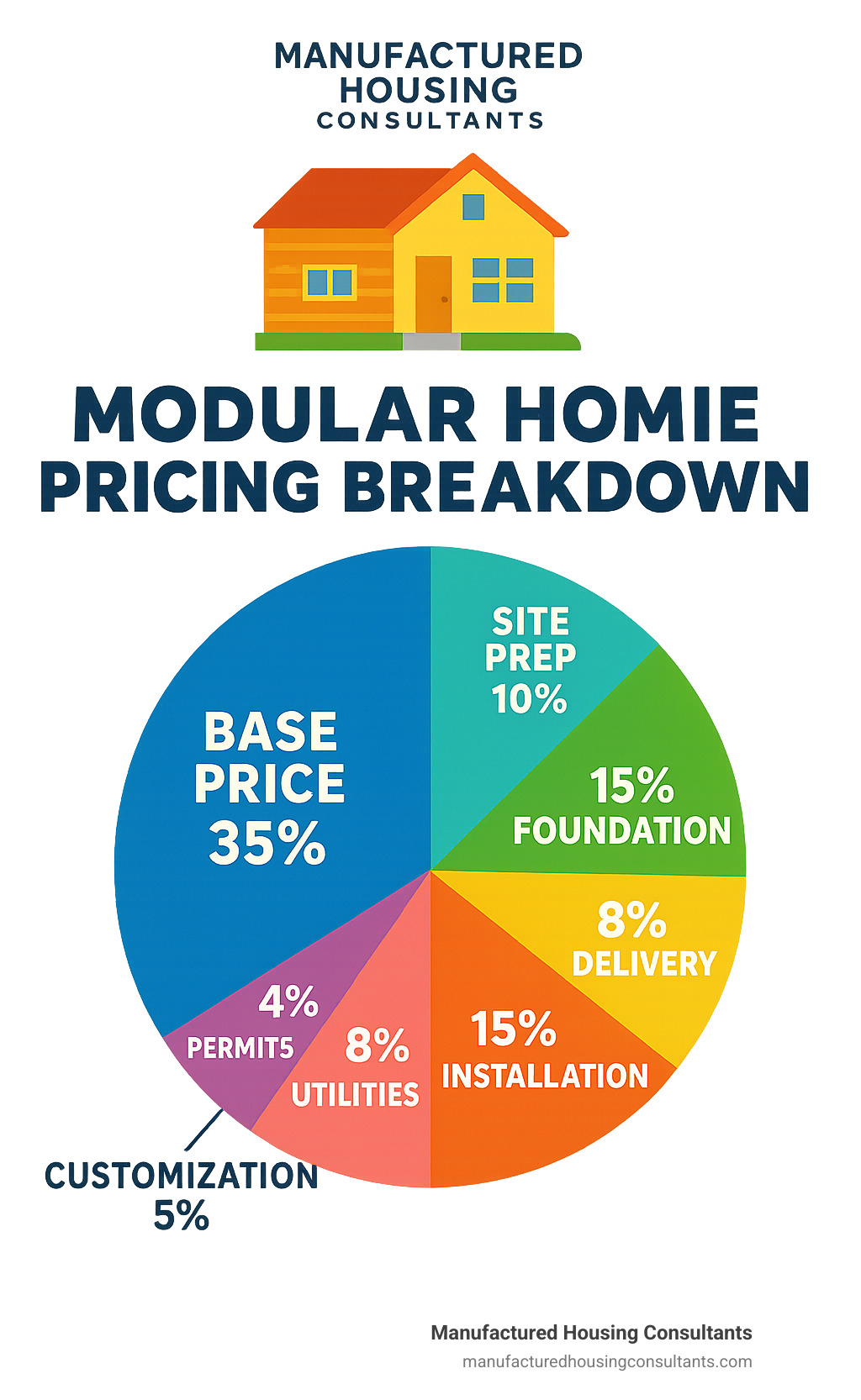

What drives these prices? The total cost includes the base home unit, delivery, site preparation, foundation, installation, utility connections, permits, and any customizations. Land costs are typically separate and vary dramatically by location.

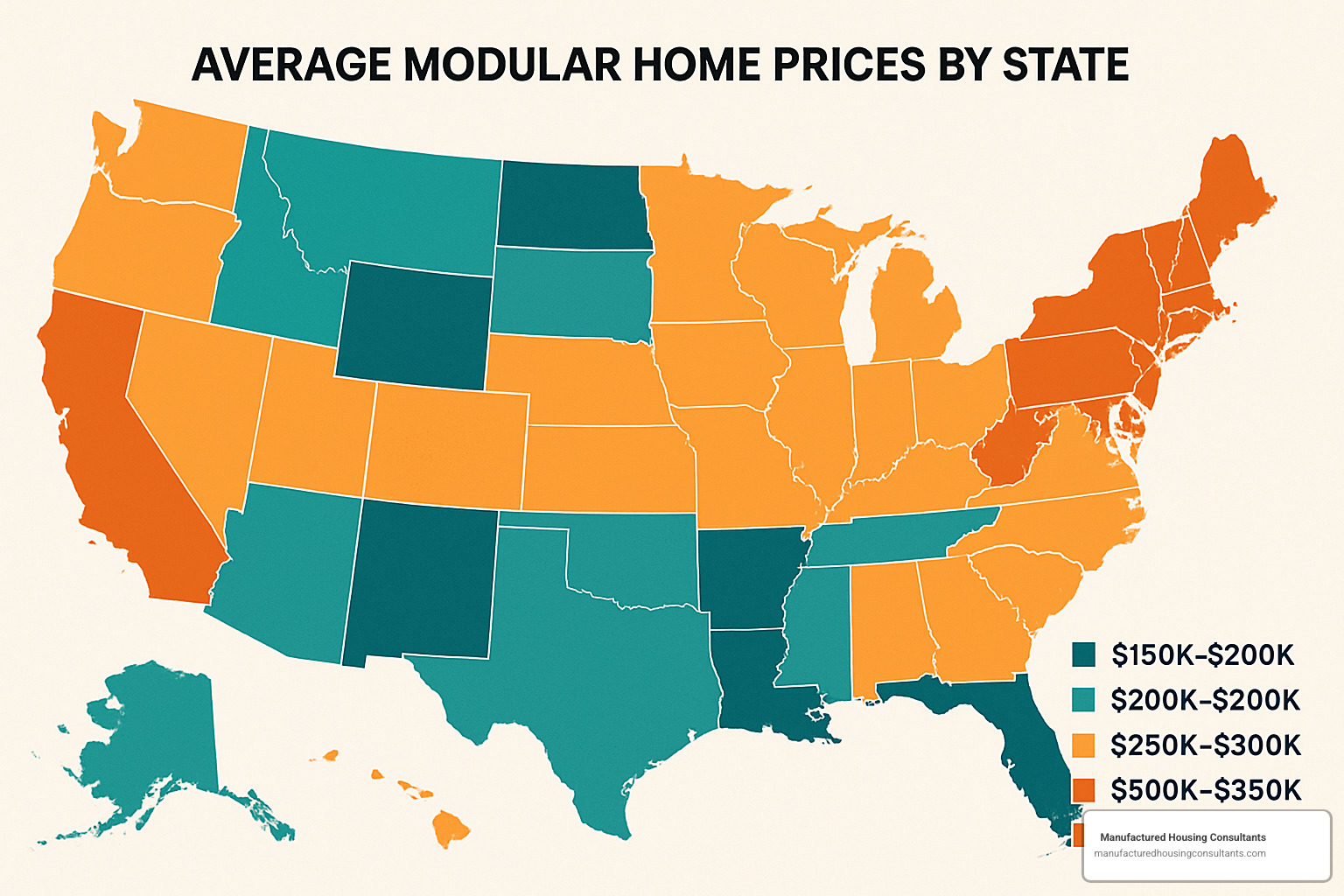

Regional differences matter too. In Pennsylvania, the average modular home costs around $143,438, while national averages hover around $270,000 for a complete project. Texas offers some of the most competitive pricing, especially for those willing to consider smaller footprints or standard designs.

Quick modular house prices definitions:

Modular House Prices Explained for 2025

Looking at the housing market in 2025, modular house prices continue to offer a breath of fresh air compared to skyrocketing traditional construction costs. While the world around us has changed, the value proposition of modular homes remains strong.

Today, you can expect to pay approximately $270,000 for a complete modular home project nationwide. For an average 1,800 square foot home, that breaks down to about $80-$160 per square foot fully installed – including everything from delivery to site prep and those finishing touches that make a house a home.

If we’re just talking about the factory-built modules themselves (before they arrive at your property), you’re looking at $50-$100 per square foot. This is your starting point before considering site work and installation.

You might be wondering why prices have shifted over the past few years. A few key factors have reshaped the landscape:

Material costs have certainly risen with inflation, though modular builders have a secret weapon – buying in bulk and minimizing waste in controlled factory environments helps offset some of these increases. After those nail-biting supply chain disruptions from 2021-2023, things have largely stabilized, giving manufacturers more predictable timelines and costs.

Factory efficiency continues to improve as modular construction becomes more mainstream. Even with wage increases, smart manufacturing processes help keep labor costs in check. And while newer energy codes require better insulation and efficiency features (adding to upfront costs), your monthly utility bills will thank you for years to come.

The regional differences tell an interesting story. In Pennsylvania, the average modular home costs around $143,438, while a comparable stick-built home starts at about $269,000 – that’s a substantial difference that could fund college educations or a comfortable retirement!

Here in Texas, we’re particularly fortunate. Our competitive market offers quality modular options starting at $90-$140 per square foot fully installed, depending on your design choices and finishes.

One important distinction to understand is the difference between modular and manufactured homes. Though both are factory-built, modular homes are constructed to the same local building codes as site-built homes and permanently attached to foundations. Manufactured homes (sometimes called mobile homes) follow a federal HUD code and come with different financing, zoning, and resale considerations.

Curious what these modern marvels actually look like inside? Take a virtual stroll through our featured modular home to see the quality and design possibilities firsthand.

Factors Influencing Modular House Prices Per Square Foot

When budgeting for your modular dream home, understanding what drives costs helps you make smarter decisions. Let’s explore what actually influences those modular house prices per square foot.

Size matters – but perhaps not how you’d think. Larger modular homes often cost less per square foot thanks to economies of scale. While that cozy 800-square-foot cottage might run $100-$160 per square foot, a spacious 2,500-square-foot family home could drop to $80-$130 per square foot. Why? Fixed costs like design, transportation, and crane rental get spread across more square footage.

The shape of your home dramatically impacts your bottom line. Those simple rectangular designs aren’t just minimalist chic – they’re budget-friendly too. Every corner, bump-out, or fancy roof line adds complexity and cost. Custom floor plans typically add $10-$50 per square foot compared to standard designs from a catalog.

Your choice of materials and finishes creates the biggest swing in pricing. Entry-level materials might keep you at the lower end ($80-$100/sq ft), but premium siding adds $5-15/sq ft, high-end cabinetry another $10-20/sq ft, stone countertops $5-15/sq ft, hardwood flooring $7-12/sq ft, and those energy-efficient windows another $3-8/sq ft. The good news? You can prioritize what matters most to you.

Geography plays a surprising role in your final price tag. Labor rates run higher in urban areas, transportation costs increase with distance from the factory, and local building codes may require specific features. Here in Texas, we enjoy more competitive pricing thanks to our manufacturing presence and relatively moderate building requirements compared to states with extreme weather concerns.

Your foundation choice creates a significant cost variable. A simple slab foundation runs $7-15 per square foot, while crawl spaces cost $8-20 per square foot. Full basements jump to $18-30 per square foot but add valuable living or storage space. Learn more about foundation types to make an informed choice.

Site conditions can throw unexpected curveballs into your budget. Steep slopes requiring extensive grading might add $5,000-$20,000, rocky soil requiring blasting another $3,000-$15,000, poor soil needing improved foundations $5,000-$20,000, and remote locations with difficult access $2,000-$10,000. A site evaluation early in the process helps avoid these surprises.

Local regulations often add hidden costs through impact fees ($1,000-$20,000 depending on municipality), architectural review requirements ($500-$5,000), and environmental mitigation (which varies widely). The U.S. Department of Housing and Urban Design offers helpful resources on building codes that might affect your project.

Finally, your customization choices create the most personal impact on pricing. Standard models from a manufacturer’s catalog provide the most affordable entry point. Minor modifications to existing plans might add $1,000-$5,000, significant customization of standard plans $5,000-$20,000, and fully custom designs $10,000-$50,000 or more.

By understanding these factors, you can make thoughtful tradeoffs – perhaps choosing a simpler roofline to afford those granite countertops you’ve been dreaming about, or selecting a more efficient rectangular design to splurge on hardwood floors throughout.

Cost Comparisons: Modular vs Stick-Built vs Manufactured

When you’re weighing housing options, understanding how modular house prices stack up against alternatives helps you make the right choice for your situation. Let’s break down the differences:

Modular homes hit that sweet spot between affordability and quality, typically costing $80-$160 per square foot fully installed. The magic happens in climate-controlled factories where efficiency reigns – less material waste, optimized labor, and protection from weather delays. Your home comes together in sections (modules) that are transported to your site and assembled, usually wrapping up in just 2-6 months from start to finish.

Traditional stick-built homes remain the benchmark most people think of when imagining homeownership. They’re built entirely on-site, piece by piece, with costs ranging from $100-$400 per square foot. That wide range reflects the almost unlimited customization possible – but comes with longer timelines (6-12+ months) and vulnerability to weather delays, contractor scheduling conflicts, and on-site inefficiencies.

Manufactured homes (sometimes called mobile homes) offer the lowest entry point at $70-$120 per square foot and the fastest completion timeline of 1-3 months. Built to federal HUD standards rather than local building codes, they provide quick, affordable housing but may depreciate over time unlike real estate that typically appreciates.

From a financing perspective, modular and stick-built homes qualify for traditional mortgages with similar terms and rates. Manufactured homes sometimes face more limited financing options, potentially with higher interest rates or shorter terms.

Here in Texas, we’ve seen modular homes save our customers 10-25% compared to equivalent stick-built options, with the bonus of moving in months earlier. These savings tend to increase with larger, more complex homes where the inefficiencies of site-built construction become more pronounced.

The line between high-end manufactured homes and entry-level modular homes has blurred somewhat in recent years. Some manufacturers now offer products that can be built to either standard depending on local requirements and your preferences.

Looking at long-term investment value, modular homes typically maintain value similarly to traditional construction, while manufactured homes may not appreciate at the same rate. This makes modular construction an excellent middle ground for buyers seeking both affordability now and solid resale value later.

Energy efficiency offers another bright spot for modular construction. The precision of factory building creates tighter seals and more consistent insulation, often exceeding minimum code requirements. This translates to lower utility bills month after month – savings that add up significantly over the years you’ll own your home.

Regional Variations & Case Studies (PA, TX, National)

The price tag on your modular dream home varies dramatically depending on where you plant your roots. Let’s explore how modular house prices shift across different regions and what real homebuyers are experiencing.

In Pennsylvania, modular homes have gained serious traction as affordable alternatives to traditional construction. The average modular home runs approximately $143,438 – a significant savings compared to stick-built homes starting around $269,000. Pennsylvania buyers often gravitate toward classic two-story Colonials and single-story ranches, with prices typically landing between $90-$170 per square foot fully installed.

One Pennsylvania family recently built an 1,800 square foot modular home in suburban Philadelphia for approximately $200,000 ($111/sq ft excluding land). They invested about $15,000 in energy-efficient features, which qualified them for $5,000 in state incentives – and now they’re enjoying lower utility bills every month.

Here in Texas, where we call home, the modular market offers particularly attractive value. Typical modular homes range from $120,000-$230,000 depending on size and features, with prices averaging $80-$150 per square foot fully installed. Our climate influences popular choices – single-story ranch designs and contemporary open-concept plans dominate, often with upgraded cooling systems and hurricane-resistant construction in coastal areas.

A recent project near San Antonio highlights the Texas advantage: a 1,600 square foot modular ranch home completed for $155,000 ($97/sq ft excluding land). The timeline was equally impressive – two weeks in the factory and just four weeks for on-site completion. The homeowners moved in less than two months after breaking ground!

Nationwide trends reveal interesting patterns. Urban installations typically cost 15-30% more than rural projects due to access challenges, higher permit costs, and steeper labor rates. Coastal areas require additional hurricane or seismic reinforcement, adding 5-15% to base costs. Northern climates need improved insulation and heating systems, adding another 3-8% to stay cozy through those cold winters.

Different home styles come with distinct price points and appeal to various lifestyles:

Tiny modular homes (400-800 sq ft) have captured imaginations and budgets at $65,000-$90,000. They’re particularly popular for urban infill lots and vacation properties. In Austin, a 600 sq ft Accessory Dwelling Unit recently cost $72,000 ($120/sq ft), providing rental income for the property owner.

Ranch-style modular homes (1,200-2,000 sq ft) remain the bread and butter of the industry at $120,000-$250,000. Their single-level living and open floor plans appeal to both young families and retirees. A 1,400 sq ft ranch in rural Texas recently cost $140,000 ($100/sq ft), offering accessibility and easy maintenance.

Two-story modular homes (1,800-3,000+ sq ft) provide growing families more space at $180,000-$350,000. Their traditional layouts with separate living areas offer privacy and room to spread out. A Pennsylvania family built their 2,400 sq ft two-story dream home for $270,000 ($112.50/sq ft).

Modular duplexes (2,000-3,500 sq ft total) have caught investors’ attention at $200,000-$350,000. They offer rental income potential or multi-generational living solutions. Near Corpus Christi, a 2,800 sq ft duplex recently cost $280,000 ($100/sq ft), providing housing for two families on a single lot.

Distance matters more than many buyers initially realize. The journey from factory to building site significantly impacts your bottom line:

- Nearby factories (0-50 miles away) keep transport fees minimal at $2,000-$5,000

- Moderate distances (50-200 miles) bump transport costs to $5,000-$10,000

- Long hauls (200+ miles) can add substantial transport costs of $10,000-$20,000+

That’s why our strategic locations in San Antonio, New Braunfels, Laredo, Corpus Christi, Victoria, and Von Ormy help minimize these transportation costs for our Texas customers.

Customizations & Hidden Modular House Prices

When budgeting for your modular home, those advertised base modular house prices are just the beginning of the story. Like buying a car, the options and upgrades can significantly change your final investment. Let’s pull back the curtain on these often-overlooked costs.

The customization journey starts with exterior choices that define your home’s character. Premium siding options like fiber cement or architectural panels add $5,000-$15,000 but offer superior durability and curb appeal. Upgraded architectural roof shingles might add $2,000-$5,000 but can last decades longer than standard options. Stone or brick accents create timeless charm for $7,000-$20,000, while improved windows ($3,000-$10,000) and custom entryways ($2,000-$8,000) improve both appearance and energy efficiency.

Inside, your personal touches transform a house into your home. Upgraded flooring ranges from $5-$15 per square foot depending on whether you choose luxury vinyl, engineered hardwood, or natural stone. Custom cabinetry adds $5,000-$20,000 but provides better storage solutions and lasting quality. Designer lighting packages ($2,000-$7,000), smart home technology ($3,000-$15,000), and premium appliance packages ($5,000-$15,000) create the atmosphere and convenience that match your lifestyle.

Sometimes you need structural modifications to suit your family’s needs. Raising ceiling heights creates airier spaces for $3,000-$10,000, while room size adjustments cost $5,000-$15,000. That extra bathroom everyone wants adds $8,000-$20,000, and significant layout reconfigurations run $10,000-$30,000. These aren’t mere cosmetic changes – they fundamentally improve how your home functions.

Beyond the main house, many families want additional structures that complete their property. A standard two-car garage adds approximately $28,000 but protects vehicles and provides valuable storage. A basic deck costs around $7,700 and creates outdoor living space for entertaining and relaxation. A full basement foundation adds $18,000-$30,000 but essentially doubles your usable space with room for storage, recreation, or future finishing. Even a matching storage building averages $2,500 but keeps lawn equipment and seasonal items organized.

Before your beautiful modules can even arrive, your land needs preparation – another significant expense many buyers overlook. Land clearing runs $1,500-$5,000 depending on vegetation density. Excavation adds $1,660-$6,710 based on soil conditions and foundation type. Proper grading ($400-$6,500) ensures water flows away from your home. Driveway installation adds $3,000-$10,000 depending on length and materials. And if your property has slopes, retaining walls might add another $3,000-$15,000.

The paperwork and permissions add up quickly too. Building permits typically cost $500-$2,000 depending on your municipality. Impact fees contribute another $1,000-$3,000 toward local infrastructure. Inspection fees add $500-$1,500 throughout the building process. Various development fees vary widely by location. Together, these permits and fees typically range from $500 to $5,000 – money you need before the first nail is driven.

Connecting to essential services creates another budget category. Water connection runs $1,000-$5,000 depending on municipal requirements and distance to the main line. Sewer hookup or septic installation adds $3,000-$10,000. Electrical service costs $1,000-$3,000, and gas line installation (if available) adds $500-$2,000. For standard sites, budget approximately $2,500 for utilities, but remote locations can double or triple these figures.

Getting your home modules to your site requires specialized equipment and expertise. Delivery fees typically run $5-$15 per mile from the factory. Crane rental adds $1,000-$5,000 depending on site accessibility and module configuration. The set crew that precisely places and connects your modules adds $5,000-$10,000.

In some states, including parts of Texas, sales tax applies to the modular home itself. This 6-8.25% can add $5,000-$10,000 to your total – a significant line item that’s easy to overlook in initial planning.

For a deeper dive into these costs, check our comprehensive Guide on Modular House Cost.

When planning your budget, a good rule of thumb is to add 30-50% beyond the base modular home price for site work, foundation, utilities, permits, and basic customizations. For a home with a $150,000 base price, your final project cost could easily reach $195,000-$225,000 before land costs. While still significantly less than comparable stick-built construction, these realistic numbers help you avoid unpleasant financial surprises along your homebuilding journey.

Getting Exact Quotes & Saving on Modular House Prices

Navigating the process of obtaining accurate quotes and finding ways to save on your modular home purchase requires strategy and knowledge. Here’s how to approach this critical phase:

Understanding the Complete Budget

Before requesting quotes, develop a comprehensive budget that includes:

- Base modular home cost

- Land purchase (if not already owned)

- Site preparation

- Foundation

- Delivery and set costs

- Utility connections

- Permits and fees

- Customizations and upgrades

- Contingency fund (10-15% of total budget)

This holistic approach prevents unpleasant surprises and helps you make informed decisions about where to allocate your funds.

Researching Financing Options

Modular homes qualify for most traditional mortgage products, but understanding the nuances can save you thousands:

- Construction-to-permanent loans simplify the process

- Some lenders offer specific modular home programs with competitive rates

- FHA, VA, and USDA loans can be used for modular homes, often with lower down payment requirements

- Energy-efficient mortgages may provide better terms for homes with qualifying features

Comparing Apples to Apples

When collecting quotes from different builders or manufacturers:

- Request itemized bids that break down all costs

- Ensure each quote includes the same scope of work

- Verify what’s included vs. what’s considered an upgrade

- Ask about warranty coverage and what it includes

- Consider the reputation and longevity of the manufacturer

Timing Your Purchase

Strategic timing can impact your bottom line:

- Winter months often see lower demand and potentially better pricing

- End-of-quarter or end-of-year purchases may benefit from manufacturers trying to meet sales targets

- Being flexible with your timeline gives you negotiating leverage

DIY vs. Professional Installation

While some aspects of modular home installation require professionals, there are areas where DIY can save money:

- Site clearing and basic preparation

- Some interior finishing work

- Landscaping and exterior features

- Deck or porch construction

However, foundation work, crane operation, and module setting should always be handled by qualified professionals.

If you’re considering purchasing land for your modular home, our guide on Things to Consider While Buying Land for Mobile and Manufactured Homes provides valuable insights that apply to modular homes as well.

Resale Value Considerations

When making decisions about customizations and upgrades, consider the impact on resale value:

- Energy-efficient features typically provide good ROI

- Kitchen and bathroom upgrades generally return 70-80% of their cost

- Outdoor living spaces are increasingly valuable in the Texas market

- Flexible floor plans that accommodate changing needs tend to appeal to more buyers

A thoughtful approach to these elements can maximize both your enjoyment of the home and its future marketability.

Step-by-Step Quote Process for Modular House Prices

Obtaining accurate quotes for your modular home requires a systematic approach. Here’s our recommended process to ensure you get comprehensive, comparable estimates:

1. Preliminary Research and Planning (1-2 weeks)

- Determine your approximate budget and financing options

- Research modular home manufacturers and their standard models

- Create a list of must-have features and nice-to-have upgrades

- Develop a rough timeline for your project

2. Land Assessment (2-4 weeks if not already owned)

- If you already own land, have a professional site evaluation conducted

- If you’re still looking for land, focus on properties suitable for modular installation

- Consider access for delivery trucks and cranes

- Evaluate utility availability and connection costs

- Check zoning regulations and deed restrictions

3. Soil Testing and Site Planning (1-2 weeks)

- Conduct soil tests to determine foundation requirements

- Identify any potential site challenges (drainage, slope, etc.)

- Develop a preliminary site plan showing home placement

- Consider future additions or outbuildings in your layout

4. Floor Plan Selection (2-4 weeks)

- Review manufacturer catalogs and standard designs

- Consider how each layout fits your lifestyle needs

- Identify any modifications you might want to standard plans

- Request preliminary pricing on 2-3 favorite models

5. Request Detailed Quotes (1-2 weeks)

When requesting quotes, ask for an itemized breakdown including:

- Base home price

- Specific customizations and their costs

- Delivery fees

- Set and finish costs

- Foundation estimates

- Site work requirements

- Utility connection estimates

- Permit fee estimates

- Warranty information

- Timeline projections

6. Quote Comparison and Negotiation (1-2 weeks)

- Create a spreadsheet comparing all quotes on the same criteria

- Identify any significant differences between quotes and ask for clarification

- Negotiate on areas where there may be flexibility

- Consider value-engineering options if quotes exceed your budget

7. Build in Contingency (Planning Phase)

- Add a minimum 10% contingency to your budget for unexpected costs

- Identify areas where you could scale back if necessary

- Prioritize structural elements over cosmetic features

At Manufactured Housing Consultants, we simplify this process for our Texas customers. We provide comprehensive, transparent quotes that include all relevant costs for your specific site and home design. Our team conducts thorough site evaluations to identify any potential challenges before they become expensive problems.

For financing guidance, we recommend reviewing our Modular Home Financing Options resource, which outlines the various loan programs available for modular home purchases.

Questions to Ask When Getting Quotes:

- What is included in the base price vs. what are considered upgrades?

- How are change orders handled during the process?

- What is the payment schedule and what triggers each payment?

- Who handles permits and inspections?

- What warranties are provided and what exactly do they cover?

- What is the expected timeline from contract to completion?

- How are delays handled and communicated?

- What are the most common unexpected costs in similar projects?

By following this structured approach and asking the right questions, you’ll be well-positioned to receive accurate, comprehensive quotes that allow for meaningful comparison between options.

Financing & Money-Saving Tips

Securing the right financing and finding ways to save on your modular home purchase can make a significant difference in your overall investment. Here are our expert tips for maximizing your budget:

Understanding Modular Home Financing Options

Modular homes qualify for most traditional mortgage products, but there are some nuances to be aware of:

-

Construction-to-Permanent Loans

- Combines construction financing and permanent mortgage

- Single closing saves on fees

- Converts automatically to a fixed-rate mortgage after completion

- Typically requires 20-25% down payment

-

FHA and VA Loans for Modular Homes

- FHA loans require just 3.5% down

- VA loans may offer 0% down for qualifying veterans

- Both have competitive interest rates

- Must meet specific property and construction requirements

-

USDA Rural Development Loans

- 0% down payment option for qualifying rural properties

- Income restrictions apply

- Property must be in an eligible rural area (many Texas communities qualify)

-

Manufacturer Financing Programs

- Some modular home manufacturers offer their own financing

- May offer more flexible terms for modular-specific situations

- Compare rates and terms with traditional lenders

Strategic Money-Saving Approaches

Beyond financing, consider these strategies to reduce your overall costs:

-

Size Optimization

- Right-size your home to your actual needs

- Consider future needs but don’t overbuild

- Smaller homes cost less to heat, cool, and maintain

-

Phased Building Approach

- Start with essential living spaces

- Plan for future additions when budget allows

- Ensure initial design accommodates planned expansions

-

Energy Efficiency Investments

- Prioritize insulation and high-efficiency HVAC

- Consider Energy Star appliances and fixtures

- Look into solar readiness even if not installing panels immediately

- These investments typically pay for themselves through utility savings

-

Tax Credits and Incentives

- Federal tax credits for energy-efficient building components

- State and local incentives for green building

- Utility company rebates for efficient appliances and systems

- In Texas, some areas offer property tax incentives for energy-efficient homes

-

Strategic Customization

- Focus upgrades on “bones” of the house (insulation, windows, HVAC)

- Choose standard sizes for windows and doors

- Select builder-grade finishes in less visible areas

- Invest in quality for high-use items (flooring, countertops)

-

DIY Where Appropriate

- Handle site clearing if you have the equipment and skills

- Tackle interior painting to save on labor

- Install your own fixtures and hardware

- Complete landscaping yourself after construction

-

Timing Your Purchase

- Winter months often see slower sales and better pricing

- End-of-quarter incentives may be available

- Model year changeovers can create opportunities for discounts

Avoiding Common Financial Pitfalls

Be aware of these potential issues that can impact your budget:

-

Underestimating Site Costs

- Always get a professional site evaluation

- Budget for worst-case scenarios with soil and grading

- Include utility connection costs in initial planning

-

Ignoring Resale Considerations

- Balance personal preferences with market appeal

- Avoid over-customization that might limit future buyers

- Focus on timeless design elements rather than trends

-

Skimping on Important Systems

- Don’t cut corners on foundation, roof, or HVAC

- Invest in quality windows and doors for energy efficiency

- Ensure proper moisture management and ventilation

-

Failing to Account for All Costs

- Include permits, impact fees, and inspections

- Budget for temporary housing if needed during construction

- Consider landscaping and driveway in total project cost

In our experience serving customers throughout Texas, those who take a methodical approach to financing and budgeting are much more satisfied with their modular home purchase. By understanding all your options and planning strategically, you can achieve significant savings while still getting the home that meets your needs.

Conclusion & Next Steps

As we’ve explored throughout this guide, modular house prices offer compelling value in today’s housing market, particularly for buyers seeking quality construction at a more affordable price point than traditional site-built homes. Let’s summarize what we’ve learned and outline your next steps.

Key Takeaways About Modular House Prices

-

Value Proposition: Modular homes typically cost 10-20% less than comparable stick-built homes while offering similar or better quality due to factory construction.

-

Price Range: Expect to pay $80-$160 per square foot fully installed, with base modules starting at $50-$100 per square foot before site work and installation.

-

Total Investment: For a complete project including foundation, site work, and finishing, budget between $180,000-$360,000 for an average 1,800 square foot home.

-

Regional Variations: Prices vary significantly by location, with Texas offering some of the most competitive pricing in the country due to manufacturing presence and moderate building codes.

-

Hidden Costs: Remember to account for site preparation, foundation, permits, utility connections, and customizations when budgeting.

-

Long-Term Value: Unlike manufactured homes, modular homes typically appreciate similarly to traditional construction, making them a sound long-term investment.

Your Path to Modular Home Ownership

If you’re considering a modular home, here’s a timeline of what to expect:

-

Research and Planning (1-3 months)

- Explore floor plans and manufacturers

- Determine your budget and financing options

- Identify potential building sites

- Research local building requirements

-

Land Acquisition and Site Planning (1-4 months)

- Purchase land if not already owned

- Conduct soil tests and site evaluations

- Develop site plan and foundation design

- Apply for necessary permits

-

Home Selection and Customization (1-2 months)

- Choose your floor plan and manufacturer

- Select customizations and upgrades

- Finalize all specifications and contracts

-

Construction and Installation (3-6 months)

- Site preparation and foundation construction

- Factory building of home modules (typically 6-8 weeks)

- Delivery and setting of modules (1-2 days)

- On-site finishing work (4-6 weeks)

-

Final Inspections and Move-In (2-4 weeks)

- Utility connections and testing

- Final building inspections

- Certificate of occupancy

- Move-in and enjoyment of your new home

Value Appreciation and Long-Term Benefits

Modular homes built to modern standards typically appreciate in value similarly to traditional homes. Factors that positively influence long-term value include:

- Energy-efficient construction reducing operating costs

- Quality materials and craftsmanship

- Thoughtful floor plans that meet market demands

- Proper siting and orientation on your property

- Regular maintenance and updates

At Manufactured Housing Consultants, we’ve helped countless families throughout San Antonio, New Braunfels, Laredo, Corpus Christi, Victoria, Von Ormy, and across Texas find their ideal modular home solution. Our experience has shown that educated buyers who understand the full scope of modular construction are consistently the most satisfied with their purchase.

Next Steps

Ready to explore modular housing options? Here are your immediate next steps:

-

Browse our selection of Modular Homes to see available floor plans and features

-

Contact our team for a personalized consultation to discuss your specific needs and budget

-

Schedule a visit to one of our locations to tour available models and experience the quality firsthand

-

Request a detailed quote that includes all aspects of your project for transparent budgeting

Whether you’re looking for an affordable starter home, a spacious family residence, or a downsized retirement solution, modular construction offers quality, efficiency, and value that’s hard to beat in today’s housing market. With proper planning and the right partner guiding you through the process, your modular home can provide decades of comfortable, efficient living at a price point that makes homeownership more accessible.