Protecting Your Investment: Understanding Types of Mobile Home Roofs

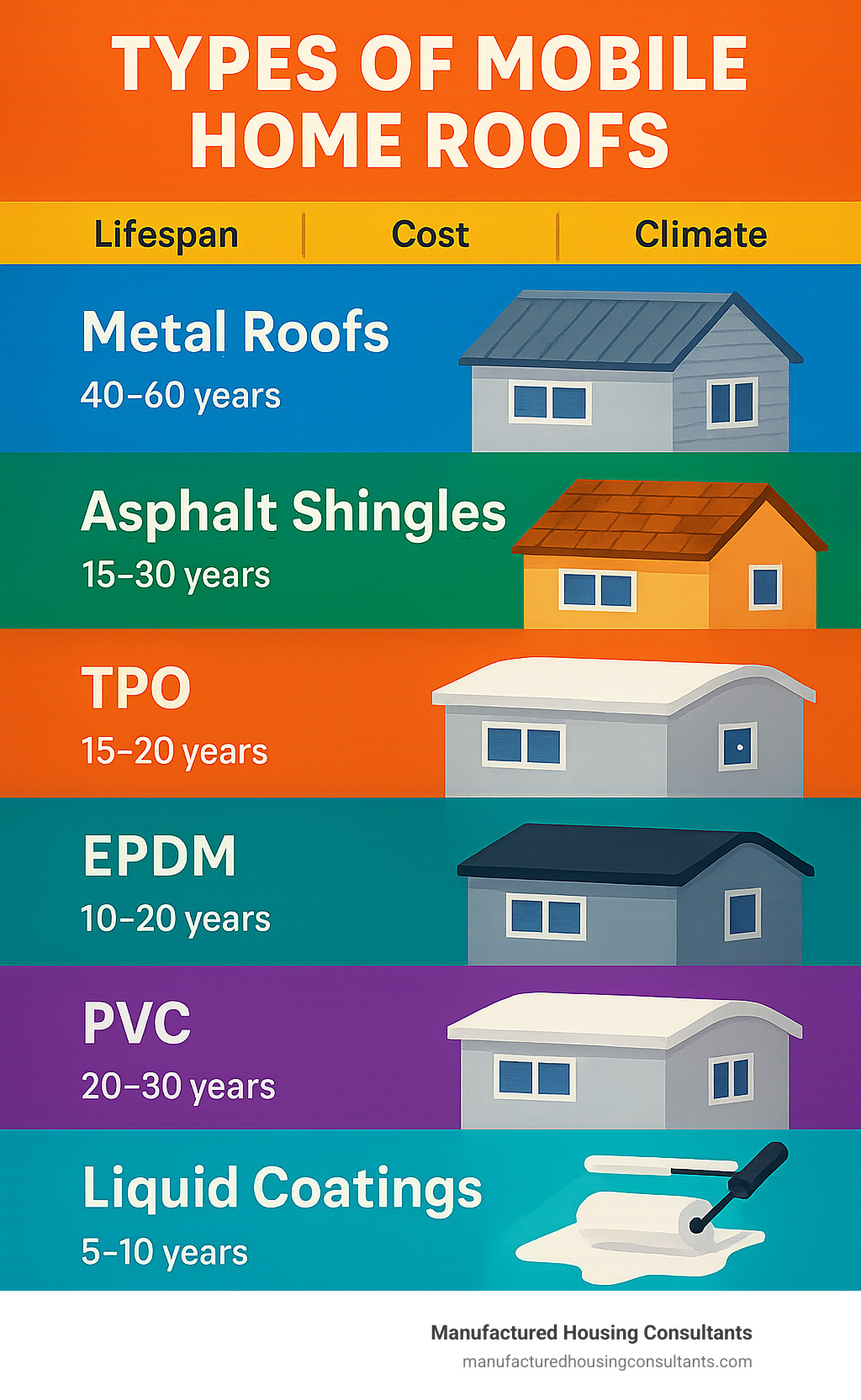

Types of mobile home roofs include:

- Metal Roofs – Longest lasting (40-60 years), excellent durability, reflective properties

- Asphalt Shingles – Budget-friendly, familiar look, 15-30 year lifespan

- TPO Membranes – Energy-efficient white surface, 15-20 year lifespan

- EPDM Rubber – Quick installation, affordable, 10-20 year lifespan

- PVC Membranes – Weather-resistant, 20-30 year lifespan

- Liquid Coatings – Emergency repair option, 5-10 year lifespan

- Pitched Roof-Overs – Added on top of existing roofs for improved drainage

Water is the most damaging force on earth, and your roof is the first shield of defense against it. When it comes to mobile homes, choosing the right roof isn’t just about keeping the rain out – it’s about protecting your investment, managing energy costs, and ensuring your home stands the test of time.

Whether you’re dealing with an aging roof that needs replacement or selecting options for a new manufactured home, understanding the different types of mobile home roofs will save you money and headaches down the road.

Mobile home roofs face unique challenges compared to site-built homes. Their structure typically supports less weight, and many older models have flat or low-pitched designs that require specialized materials. The average mobile home roof replacement costs around $5,000, but prices can range from $1,000 for basic materials on a small home to over $8,000 for premium options on a double-wide.

Your climate plays a crucial role in determining the best roof for your situation. In Texas and other hot regions, reflective materials like white TPO membranes or metal roofing with heat-reflective coatings can reduce cooling costs by up to 40%. For areas with heavy rainfall or snow, pitched roof designs with proper drainage are essential.

The shape of your current roof also matters – flat, bowed, or pitched designs each have ideal materials that work best with their structure. Mobile homes built before 1976 typically came with flat or bowed roofs that may require different solutions than newer models with truss systems.

Types of mobile home roofs helpful reading:

Comparing the 7 Best Types of Mobile Home Roofs

When it’s time to replace your mobile home roof in Texas, you’ll want to understand how each option performs in our unique climate. Here at Manufactured Housing Consultants, we’ve helped countless homeowners across San Antonio, Corpus Christi, and throughout Texas find the perfect roofing solution that works for both their needs and budget. Let’s explore the details of each option.

Metal Roofs: The Gold Standard Among Types of Mobile Home Roofs

If you’re looking for the cream of the crop when it comes to types of mobile home roofs, metal simply can’t be beat—especially in our Texas heat where durability and heat reflection are must-haves. With proper care, these tough-as-nails roofs can last an impressive 40-60 years, and sometimes even up to 80 years!

Think of metal roofing as the marathon runner of roofing materials. While other options might sprint out of the gate with lower prices, metal roofs go the distance with superior longevity that outlasts virtually everything else on the market. They stand up beautifully to our high winds (crucial if you’re near the coast in places like Corpus Christi), and their reflective surfaces can slash your cooling costs by up to 40%—no small consideration during those sweltering Texas summers.

You’ve got two main choices when it comes to metal: aluminum (which never rusts but costs more) or galvanized steel (excellent durability at a friendlier price point). Most of our customers opt for the latter since it offers the best bang for your buck.

Price-wise, expect to pay $1,000-$2,000 for materials only on a single-wide, or $3,000-$4,000 if you add insulation and professional installation. Double-wides run about $1,800-$3,000 for materials alone, or $7,000-$8,000 fully installed with insulation.

“But what about the noise when it rains?” I hear you asking. It’s a common concern, but adding proper insulation beneath those metal panels solves the problem beautifully while also improving your home’s energy efficiency. We typically recommend including this insulation despite the extra upfront cost—it prevents future headaches and extends your roof’s life.

| Feature | Metal Roofing | Asphalt Shingles |

|---|---|---|

| Lifespan | 40-60+ years | 15-30 years |

| Initial Cost | Higher ($4-6/sq.ft.) | Lower ($2.50-4.50/sq.ft.) |

| Energy Efficiency | Excellent (reflects heat) | Fair to Good |

| Weight | Lightweight | Heavier (240 lbs/square) |

| Maintenance | Minimal | Regular |

| Wind Resistance | Excellent (120+ mph) | Good (60-90 mph) |

| Installation Time | 1-2 days | 1-3 days |

| Long-term Value | Excellent | Good |

If you’re planning to stay in your mobile home for the long haul, metal roofing delivers the best return on investment despite the higher initial cost. And while you’re upgrading your roof, why not consider some interior improvements too? Check out our Mobile Home Interior Design Ideas for inspiration.

Asphalt Shingle Roofs: Affordable & Familiar

When it comes to types of mobile home roofs, asphalt shingles remain a crowd-pleaser for good reason. They’re budget-friendly and give your home that traditional look that many of our San Antonio customers love.

What makes shingles so popular? For starters, they’re incredibly cost-effective—typically around $1,500 for a single-wide and $2,500-$3,000 for a double-wide. They come in countless colors and styles to match your home’s personality, and if a section gets damaged, you can replace just those shingles rather than tackling the whole roof.

There’s also something to be said for familiarity. Most of us grew up with shingle roofs, and there’s a comfort in choosing something that feels known and trusted. For the handy homeowner, they’re also more DIY-friendly than some of the more specialized roofing systems.

That said, mobile homes have special considerations when it comes to shingles. Because of structural limitations, your mobile home roof can typically support only a single layer of shingles. Each square (100 sq. ft.) adds about 240 pounds to your roof—meaning a typical mobile home using nine squares would add over 2,160 pounds. That’s a lot of weight for those trusses to handle!

Shingles generally last 15-30 years, putting them squarely in the middle of the pack for longevity. Just be aware that our Texas heat can be tough on them—they might deteriorate faster here than in cooler climates, and dark-colored shingles absorb more heat, potentially driving up your cooling costs.

That shingles only work on pitched roofs (not flat or bowed designs), usually require removing the existing shingles first, and offer less wind resistance than metal (something to consider if you’re near the coast in Corpus Christi).

TPO Membranes: High-Tech, Energy-Smart

If your mobile home has a flat or low-sloped roof, Thermoplastic Polyolefin (TPO) membrane might just be your new best friend. This single-ply roofing option has become one of the most popular high-tech types of mobile home roofs in recent years—and for good reason.

Think of TPO as your roof’s personal sunscreen. Its bright white surface reflects up to 87% of the sun’s UV rays, which can dramatically reduce your cooling costs during those scorching Texas summers. It’s like having a giant reflector on top of your home, bouncing that heat right back where it came from instead of absorbing it into your living space.

Beyond its impressive energy efficiency, TPO is remarkably durable. It resists mold, dirt buildup, tears, and punctures—all while remaining lightweight enough not to stress your mobile home’s structure. The heat-welded seams create a watertight barrier that keeps the rain where it belongs—outside.

TPO typically lasts 15-20 years and costs about the same as asphalt shingles, but with superior energy performance in our hot Texas climate. One advantage that homeowners appreciate is TPO’s flexibility in seam widths, which can help reduce installation costs.

We strongly recommend professional installation for TPO roofing. Those heat-welded seams need to be done right—improper installation can lead to rippling and leaks that defeat the purpose of your new roof. When properly installed, though, TPO excels on mobile homes with flat or low-pitched roofs where water drainage is a concern.

For folks in sun-baked locations like San Antonio or Laredo, the energy savings from a white TPO roof can be substantial. To maximize these benefits, consider upgrading your window treatments too—our guide on Window Coverings Ideas Available for Manufactured Homes or Mobile Homes offers perfect complementary options.

Learn more about TPO roofing and its benefits from Forbes Home Improvement’s guide to TPO roofing.

EPDM Rubber Roofs: Fast DIY Roof-Over

Among all the types of mobile home roofs, EPDM rubber might be the most DIY-friendly option out there. This synthetic rubber membrane (don’t worry, I can’t pronounce Ethylene Propylene Diene Monomer either!) offers a straightforward installation process that won’t break the bank.

The beauty of EPDM is its simplicity. With basic tools like a hammer and utility knife, you can transform your roof in less than a day. Materials typically cost $1,175-$2,295 for a single-wide and $1,595-$3,610 for a double-wide. For the handy homeowner, this accessibility makes EPDM particularly appealing.

EPDM comes in large sheets that minimize or eliminate seams—often the weak points in any roofing system. The material performs impressively in both extreme heat and cold, making it well-suited to our sometimes unpredictable Texas weather patterns.

These rubber roofs typically last 10-20 years, though proper installation and regular maintenance are key to reaching the upper end of that range, especially under the intense Texas sun. You have two color choices: black (more common and less expensive) or white (better reflectivity and energy efficiency). For homes in hot spots like San Antonio or Laredo, that white membrane can make a noticeable difference in your summer cooling bills.

For the best performance, we often suggest adding a polystyrene insulation layer beneath the rubber membrane. This adds $500-$700 for a single-wide or $1,400-$1,800 for a double-wide, but improves energy efficiency and extends your roof’s life—a worthwhile investment for most homeowners.

One thing to note: EPDM requires more maintenance than some other options. Plan on resealing every 2-3 years to maintain its waterproof integrity, and schedule annual inspections to catch any potential issues early.

EPDM shines as a “roof-over” solution—installing directly over your existing roof after necessary repairs and preparation. This approach saves on removal costs and minimizes disruption to your daily life.

PVC Membranes: Heavy-Duty Weather Shield

When it comes to types of mobile home roofs that can truly stand up to Mother Nature’s worst, PVC membrane roofing deserves special attention. This tough-as-nails single-ply membrane offers exceptional protection, especially for mobile homes in storm-prone areas like coastal Texas.

Think of PVC as the heavyweight champion of mobile home roofing. It delivers superior durability with a typical lifespan of 20-30 years when properly installed. What sets it apart is its remarkable resistance to chemicals, oils, and greases—substances that can degrade other roofing materials over time.

For safety-conscious homeowners, PVC’s fire retardancy is a major selling point. It meets or exceeds fire safety standards for mobile homes, achieving the highest Class A fire rating. This is particularly important for manufactured homes, which must comply with specific HUD fire safety requirements.

The magic of PVC lies in its heat-welded seams, which create a watertight, single-piece surface that resists wind uplift better than many competing systems. For mobile homes in hurricane-prone areas like Corpus Christi or Victoria, this superior wind resistance provides invaluable peace of mind during storm season.

Cost-wise, PVC runs approximately $4-6 per square foot installed—placing it in the mid-to-high range for mobile home roofing. For a single-wide, expect to pay $3,000-$4,500, while a double-wide installation typically costs $5,500-$8,000.

Like TPO, PVC’s reflective properties make it an excellent choice for our hot Texas climate. White PVC membranes reflect a significant portion of solar radiation, helping keep your home cooler and reducing air conditioning costs during our seemingly endless summer months.

Environmentally conscious homeowners will appreciate that PVC is highly recyclable at the end of its useful life, making it a responsible choice that aligns with sustainable values while still delivering top-tier performance.

Liquid Coatings & Roof Wraps: Emergency Fix for All Types of Mobile Home Roofs

Sometimes you need a quick fix for a leaky roof when a full replacement isn’t in the cards just yet. That’s where liquid roof coatings come in—possibly the most affordable emergency solution among all types of mobile home roofs.

These elastomeric coatings are like giving your aging roof a new lease on life. They’re extremely affordable, typically running $600-$900 for a single-wide and $1,400-$1,800 for a double-wide. With basic tools like paint rollers, you can apply these coatings in just a few hours—no specialized equipment required.

What makes these coatings particularly appealing is their versatility. They can be applied directly over almost any existing roofing material—metal, rubber, or asphalt—without the need for tear-off. Once cured, they create an immediate waterproof barrier that protects your home from Texas’s sometimes unpredictable weather.

The white versions offer excellent reflective properties, improving energy efficiency by bouncing heat away from your home rather than absorbing it. This can make a noticeable difference in your cooling bills, especially in our hotter regions.

Liquid coatings typically last 5-10 years—shorter than other roofing options, but valuable as a stop-gap measure when budget constraints prevent a full replacement. They’re particularly effective on flat or bowed mobile home roofs common in older models built before 1976.

The application process is straightforward enough that many homeowners tackle it themselves:

For best results, apply these coatings on a mild, dry day with several hours available for curing before any potential rainfall. In our Texas climate, early morning application often works best to avoid the extreme afternoon heat.

That liquid coatings require more frequent maintenance than other roofing options. Plan on recoating every 2-3 years to maintain that waterproof barrier, and perform annual inspections to identify any areas needing touch-up.

While not a permanent solution, these coatings excel at extending the life of an otherwise sound roof, addressing emergency leaks when you’re on a tight budget, improving energy efficiency with their reflective properties, and buying you time to save for a more permanent solution.

For mobile homeowners in San Antonio, Laredo, or other sun-baked Texas locations, the cooling benefits of white elastomeric coatings can provide welcome relief during our seemingly endless summers.

Conclusion & Next Steps

After exploring all the types of mobile home roofs, you might be wondering which one is truly right for your Texas home. Trust me, I understand – it’s a big decision that impacts not just your wallet but your comfort for years to come.

Here in the Lone Star State, our unique climate demands thoughtful consideration. Those scorching San Antonio summers call for different solutions than the hurricane threats along the Corpus Christi coast. Your existing roof shape matters too – what works beautifully on a pitched roof might spell disaster for a flat one.

For our Texas heat, reflective materials make a world of difference. White TPO membranes, white EPDM, or metal roofs with reflective coatings can slash your summer cooling bills by reflecting the sun’s intense rays. I’ve seen homeowners save hundreds each year just by making this one smart choice.

If you’re in hurricane territory near Victoria or Corpus Christi, wind resistance becomes your priority. Metal and PVC membranes shine here, standing strong against those coastal gusts that can tear lesser materials to shreds.

The shape of your roof naturally guides your options. Flat or bowed roofs (common in older mobile homes) work beautifully with membrane systems like TPO, EPDM, and PVC. If you’ve got a pitched roof, you’re in luck – virtually all options remain on the table, including budget-friendly asphalt shingles.

Speaking of budgets – we all have them! For immediate solutions that won’t break the bank, asphalt shingles, EPDM rubber, or liquid coatings offer relief. But if you’re thinking long-term investment, nothing beats metal roofing’s impressive 40-60 year lifespan.

Many homeowners wrestle with the roof-over versus replacement question. Roof-overs save money upfront by eliminating removal costs, create less mess and disruption, add an insulation layer, and can improve drainage with thoughtful design. On the flip side, full replacements let you inspect and repair any hidden structural issues, upgrade insulation and ventilation, and often last longer without concealed problems.

Whatever material tops your home, regular maintenance is your roof’s best friend:

- Metal needs annual inspections with special attention to fasteners and debris removal

- Asphalt shingles benefit from twice-yearly checks and prompt replacement of damaged sections

- Membrane systems (TPO/PVC/EPDM) require annual inspections with focus on seams and flashings

- Liquid coatings need yearly inspections with recoating every 2-3 years

Your roof significantly impacts resale value. A quality roof installation can boost your home’s worth by thousands and make it far more attractive to potential buyers. It’s not just protection – it’s an investment.

At Manufactured Housing Consultants, we’ve helped countless Texas homeowners from Von Ormy to New Braunfels find their perfect roofing match. We understand the unique challenges our climate presents and the specific requirements of manufactured homes.

Ready to learn more about improving your mobile home? Check out our guides on Mobile Home Renovations: Tips and Tricks and More info about choosing the right home.

The right roof does more than just keep you dry – it transforms your home’s appearance, energy efficiency, and comfort. Whether you’re patching an emergency leak or planning ahead, you now have the knowledge to make a choice that will protect your Texas home for years to come.